Field of Application

"With accumulated skill and experience

We will be reborn as a global sterilization company."

Medical Device

Sanitization of medical devices and public health products

ISO9001, ENISO11137, ENISO 13485 Quality Systems are certified, and Soyagreentec, registered with the US FDA as a gamma ray sterilization facility, will be part of the technical development that customers need.

- Buyers are preferred to gamma-sterilized productsand are recognized as the safest sterilization methods in domestic hospitals

- Since it can be sterilized in the state of the finished product, secondary contamination does not occur.

- The gamma ray sterilization certificate and the indicator for the gamma ray attached to the product make it easy to confirm that it is a sterilized product by color change.

- You can design and use cheap packaging through various wrapping paper.

- Because there is little temperature change, it is possible to sterilize heat-sensitive products.

- Compared to EO GAS sterilization, no residual toxic substances remain.

- The sterilization assurance level (SAL: 10-2-10-6) can be optionally determined according to the purpose of use.

- Soyagreentec contributes to enhancing the competitiveness of domestic and export companies in accordance with international standards.

Using Product

Such as syringe, needle, scalpel), implant wound dressing, disposable band, razsite, artificial bone, surgical glove, suture, bandage, one needle, needles, Vulnerable bags, lids, lenses, filtration filters, sterilization tapes, and other products requiring sterilization

Food industry

It is an environmentally friendly technology recognized by WHO, FAO, IAEA, and FDA.

Irradiation of Foods

Purpose of Radiation Technology

Food preservation management, food safety, food safety, food processing and process improvement, international food trade activities

Microbiological safety function

Quality control certainty, distribution safety and period extension

Using characteristics of food processing

- Ensure permeability of finished products (prevent secondary contamination)

- There are no factors such as heat, humidity, pressure, and chemical fumigant during the process.

- It is made up of mass consecutive works.

- It is possible to produce products without harmful additives such as preservatives.

- It is a simple process and is managed in time.

- As a cold sterilization method that does not raise the product temperature, nutrient destruction is less.

Using range

- Pest control and parasitic killing

- Adjusting the ripeness of agricultural products, extending shelf life, securing distribution safety and extending the period

- Microbial sterilization, complete sterilization, reduced number of living cells

- Prevention of food poisoning by decaying bacteria and pathogens

- Mycotoxin production inhibition

- Improvement of physical properties (eg, improvement of extraction and filtration when agar is extracted due to change of viscosity, increase of extracting rate of active ingredient of herbal medicines and shortening of time)

Cosmetics

Production of products without harmful microorganisms It is possible by sterilization of gamma rays.

Irradiation of Cosmetics

- Production of finished products without microorganisms by sterilization of natural raw materials

- Sanitization of herbal ingredients, processing of contaminated containers, various packaging materials and raw materials

- Reliable sterilization (prevention of secondary contamination) with fully enclosed sealing structure

Using gamma rays is the development of new clean products.

Disposable products such as Oriental packs and Hwangto packs, which are free from harmful preservatives and preservatives, are used to produce clean, natural products without microorganisms.

It is top quality of the product to be operated and recommended by overseas buyers

Brushes, containers, and wigs made of animal hair are most likely to use gamma rays and will simplify quarantine for exported products.

Sterilization from raw materials to finished products is possible.

- Production of high-value-added products - Reduction of chemical preservative added to the skin or production of fragrance using gamma-ray

- Decolorize botanical extracts and improve function

- Improving the moisturizing effect of raw materials such as cellulose (CMC)

- Application by change of physical properties of starch, gelatine, saccharides, polyethylene glycol (PEG), etc., development of new material: Polymerization

Using Product

Mineral powder such as talc, kaolin and loess powder, deep water, herbal medicine liquid and powder, walnut powder, chlorophyll color decolorization, disposable mask pack, wrapping paper, mask sheet, packing container etc.

Medicine

It is fully realized in one day by using specific microorganisms, ordinary bacteria, fungi and other microorganism sterilization, gamma ray facilities

Irradiation of Pharmacetical

Gamma ray irradiation method is the most reliable quality process for microbial sterilization from raw materials to finished products

Quality control

- Minimize changes in product variability, nutrient breakdown, potency and content.

- It is possible to produce products that do not contain preservatives or minimize its content.

- There is no burden on the manufacturing schedule with about 24 hours processing process.

- It can be completely sealed to prevent secondary contamination.

- The center of the raw material container and microorganisms inside the pills are completely sterilized.

Processing Advantages

- Gamma rays penetrate into the inside of the product, enabling uniform and complete processing

- It is cold sterilization method that does not cause impact, pressure, temperature, moisture factor.

- It is a safer, cleaner and less hazardous residue than other methods of sterilization.

- Sterilization process Reduction of investment cost

- Environmentally friendly products can be produced and developed (preservatives, reduced use of preservatives and no use)

- Reduce manpower and time due to normal sterilization of manufacturing process

Using Product

Finished products, raw materials, oriental raw materials, containers, packaging paper, etc.

Polymer material

Polymer materials such as rubber or synthetic resin The properties change when irradiated.

Improvement of physical properties of polymer materials, development of new materials is possible by irradiation of gamma rays.

Applying technology

- There are large changes of branches, polymerization, GRAFTING, crossing, and decomposition.

- Polymerization: small molecules connected to form large molecules

- Grafting: the reaction of polymeric functional groups to ionize and branching

- Cross-linking: the reaction of neighboring molecules to each other

- Decomposition: In contrast to synthesis, large molecules break into small molecules

Advantages of Gamma Irradiation

- Polymer crosslinking at low temperature without applying pressure

- New products can be made more diverse than conventional chemical methods

- Produce reproducible products with only the dose without additives

- Simple curing process and speed of composite material is fast.

Applications

- Polymer switches, latex manufacturing, materials for aviation and marine and sporting goods, hydrogels

- Latex condoms and gloves, heat shrink tubing, wood plastic composite production, building materials

- Development of tiles, new materials, and textile remobilization using waste tire

Experimental Supplies

Experimental Supplies01

Petri dish, disposable pipette tip, sterilization filter, aseptic gloves, aseptic, aseptic, etc.

Gamma-ray sterilization method can increase the completeness of experimental supplies.

Advantages of Gamma Irradiation

- Secondary contamination does not occur because it is wrapped in finished product.

- Continuous mass sterilization process is possible.

- It is a sterilization method with a high preference for buyers for export products.

- It is managed by the application of international standards.

Experimental Supplies 02

The birth of sterilized animal feed with minimal nutrient destruction

Disadvantages of high pressure steam sterilization / EO gas sterilization

High pressure steam sterilization

- Pelletized feed curing

- Poor growth of young animals

- palatability or component change occurred

EO gas sterilization

- The sterilizing effect is insufficient.

- Disintegrate nutrients such as vitamins and amino acids.

- toxic problems caused by residual gas

- A decrease in birth rate is reported.

Only the gamma sterilization method is available in a fully packaged state.

The microorganisms contaminated to the inside are completely killed, and it is born as an aseptic feed.

LAB Animals

Advantages of Gamma Irradiation

- Protein is almost unchanged.

- Amino acid content is almost unchanged.

- Vitamin content breakdown is less than other sterilization methods.

- The growth condition is the best.

- Sterilization is possible in the state of finished product.

- The shape of the feed does not change.

Application

Litter, feed, aseptic milk powder, etc.

| Vitamin | No treatment (contrast) | Radiation (30 kGy) | Radiation(60kGy) | Steam (120℃-20분) |

|---|---|---|---|---|

| Vitamin B1 | 23.8㎍/g | 23 | 21 | 8.8 |

| Vitamin B2 | 39.7㎍/g | 39.5 | 39.9 | 36.4 |

| Vitamin B4 | 8.64㎍/g | 8.04 | 7.08 | 5.2 |

| Vitamin B12 | 0.0107㎍/g | 0.00138 | 0.00712 | 0.00388 |

| Inositol | 0.56 mg/g | 0.55 | 0.54 | 0.44 |

| Folate | 2.24㎍/g | 2 | 2.1 | 1.28 |

| Vitamin A | 22IU/g | 19 | 18 | 18 |

| Vitamin E | 340㎍/g | 310 | 320 | 320 |

Changes in Vitamin Content in Pelleted Diets for Laboratory Animals

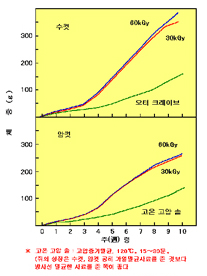

The mouse's weight gain curve

Etc

01Use in aseptic packaging and containers production industry

With the introduction of HACCP, which is a food intensive care standard for food, the process of sterile packaging during the food process is considered very important.

02Used for pet food and fish feed

Feeds can cause contamination of various germs and pathogens and parasites. This is not a problem, but a reality that can be transmitted to people through infection routes. So the US FDA is using gamma sterilization technology to manage the infectious pathway of acquired infectious agents.

03Use for quarantine items

The permeability of gamma rays is attracting attention as a quarantine treatment technology in international trade. It is used as a replacement technology for insect pests, germs and molds and chemical quarantine methods in natural fiber materials, dolls, toys.

04 Used in agricultural gardening goods

The Netherlands and other European countries, It is mainly used to prevent insect pests and larvae, bacteria and fungi that are polluted inside, and to prevent weed germination. It is used for agricultural irrigation mats, flower pots, pepper supports, pots, beehives, and seedlings

05Preservation of cultural properties

Using gamma ray technology for archival preservation of ancient documents and wooden cultural property.

06Coloring of jewels and glass

When gamma rays are applied to glassware, artificial insemination and artificial accessories, coloration of various concentrations is created and various products can be produced.