Facilities Status

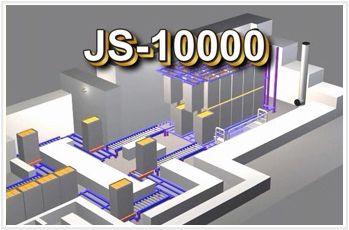

JS-10000

The JS-10000 gamma-ray irradiation facility, installed in Soyagreentec,

is the safest and most eco-friendly state-of-the-art facility introduced by Canada MDS-Nordion.

MDS-Nordion has installed approximately 200 gamma radiation research facilities in more than 50 countries since 1960 and has the world's leading technology. Among them, the JS-10000 installed in Soyagreentec is a state-of-the-art facility with only 15 installations worldwide, and is a research facility that is independent from the product's processing process, Reserch.

Using the Research Loop, sample samples of this product prior to its investigation determine the appropriate dose for the quality criteria (content, aroma, colour, viscosity, container change, etc.)

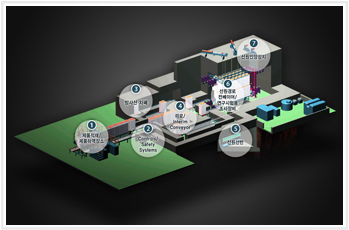

TLarge-scale process using Tote Box (Master Irradiation Process)

The Tote, which enters the chamber along the automatic Conveyor System, moves along the optimized geometric layout between the gamma-ray source and the product to ensure high absorbed dose uniformity in series

Research Loop

Research loops are used for research and sample development to determine appropriate dose, validation and other activities such as product processing process.

ISO 11137, EN 522, or AAMI, the verification dose required by a 10-2 or 10-1 SAL is precisely required. This facility is the only research and testing facility in the world that is equipped with Soyagreentec in Korea.

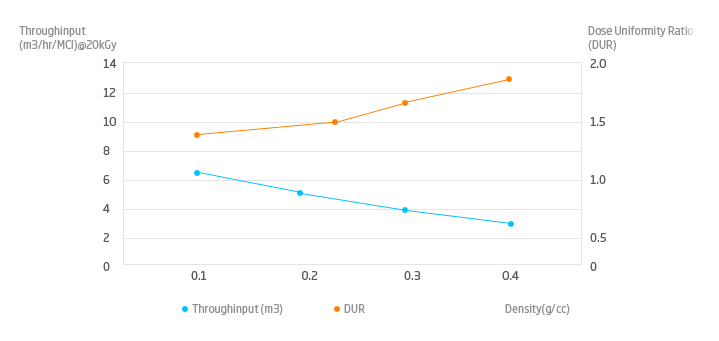

Uniformity

The gamma-ray processing process has unique characteristics and varies greatly from the survey model depending on the size and density of the loading product, the path of movement of the product, the way the product is loaded, and the geometric layout between the product and source. In order to handle the process sufficiently without exceeding the dose range required by the customer, JS-10000 reduce these deviations as much as possible, enabling highest-quality sterilization through more efficient and optimized processors.

Absorbed dose assessment (Routine Dosimeter)

| Separation | Red | Amber |

|---|---|---|

| Product pict |  |

|

| Application Dose | 5 ~ 50kGy | 1 ~ 30 kGy |

| Measurement wavelength | 640mm | 651mm |

| Purpose of use | Medical Products | Food |

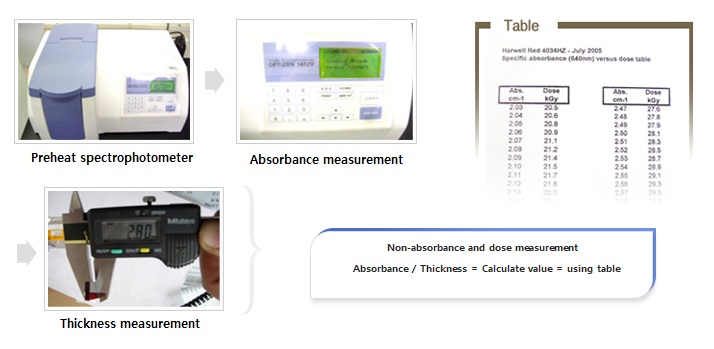

Absorbed dose reading method

Soyagreentec Routine Dosimeter is calibrated by manufacturing lot using Ceric Cerous (Reference Dosimeter).

Comparison before and after a dosimeter survey

Before and after the irradiation of the Amber dosimeter (9.75 kGy)

Before and after irradiation of Red dosimeter (22.5 kGy irradiation)

Bar-code System

Each of the irradiated products is equipped with a chemical indicator that can check whether the irradiation has been done so that it can visually check whether the irradiation has been done or not. The Bar-code system, in which information on all survey situations and products are entered, Is possible

Safety

The radiation shield of the Soyagreentec facility has been constructed with 2 to 2.5 m rebar coating according to international standards, It is systematically and safely controlled by periodically monitoring for gamma ray leakage outside of the shielding.

A double sealed source (Co-60) in stainless steel is mounted on the source shelf (rack) and under no circumstances will it be leaked.

When not in use, the source is stored in a tank at a depth of 6.6 m to shield radiation. Water in the tank is circulated by a 24-hour water purifier, which is managed and displayed by a dedicated computer program. In addition, if any safety defects are found, including the overconfiguration of the product, the source will automatically fall into the tank to protect and ensure safety.

All data related to the management room operation is automatically saved to the computer and is monitored by the Visual TV. Real time online repair is possible 24 hours a day in real time by a professional maintenance worker at MDS Nordion, the contractor, in the event of a control computer malfunction.

Facilities can also protect ships and products from natural disasters such as earthquakes and floods, as well as scrinker systems that protect the product in the event of a fire.

NORTRACK SYSTEM

We have established a fast and accurate advanced sterilization system by automating work process and logistics.

The Nortrack Computer System is a computerized, fully automated system for state-of-the-art inspection systems that provides complete control over the current state of the facility, the process information being processed, the status of the product and the time it takes to complete the process

PDA logistics system

Establishment of automation system of work procedure based on ISO standard

It is operated as PDA (Personal Digital Assistant) hand terminal and barcode. It inquires sterilization work information through on-site monitor (touch screen) and automates confirmation and approval work according to ISO standard.

Working Flow

Tote enters the inspection room along with the automatic conveyor system, moves along the optimized geometry layout between the gamma source and the product, has high absorbed dose uniformity, and treats large quantity of products safely continuously.

01 Receiving

- Receiving registration

- Receiving approval

- Receiving inspection

Standardization of receiving registration and fast and accurate warehousing approval and inspection procedures using automation system

02 plan

- Work plan

- Plan approval

Work plan and quality control room approval by standardized work process of automation system

03 Process

- Process work registration

- Process approval

- Issuing Certificates

System of process automation work process certificate issue (registration, certification, issue) with barcode recognition

04 Shipment

- Shipment regist

- Shipment approval

After completion of the sterilization process, logistics work by confirming the PDA on site

PDA Automation System

PDA Program

| 1.Receiving registration |

|

|---|---|

| 2.Receiving status |

|

| 3.Shipment registration |

|

| 4.Shipment status |

|